Graphene, or the expected revolution in electronics: coming soon

Thibaut Lalire, IMT Mines Alès – Institut Mines-Télécom

“Material of the 21st century,” a “revolutionary material”: these are some of the ways graphene has been described since it was discovered in 2004 by Konstantin Novoselov and Andre Geim. The two scientists’ research on graphene won them the Nobel Prize in Physics in 2010. But how do things stand today – seventeen years after its discovery?

Graphene is known worldwide for its remarkable properties, whether mechanical, thermal or electrical. Its perfect honeycomb structure composed of carbon atoms is the reason why graphene is a high-performance material that can be used in numerous fields. Its morphology, in the form of a sheet just one atom thick, makes it part of the family of 2D materials. Manufacturers have stepped up research on this material since its discovery, and a wide range of applications have been developed, in particular by taking advantage of graphene’s electrical performance. Many sectors are targeted, such as aeronautics, the automotive industry and telecommunications.

Is there graphene in airplanes?

Graphene is used for its status as a champion of electrical conductivity, as well as for its low density and its flexibility. These properties allow it to join the highly exclusive club of materials used in aeronautics.

Lightning and ice buildup are problems frequently encountered by airplanes at high altitudes. The impact of a lightning strike on a non-conductive surface causes severe damage that can even include the aircraft catching fire. The addition of graphene, with its high electrical conductivity, makes it possible to dissipate this high-energy current. Airplanes are designed in such a way so as to route the current as far as possible from risk areas – fuel tanks and control cables – and therefore prevent loss of control of the aircraft, or even explosion.

The history of graphene starts here. Umberto/Unsplash, CC BY

A coating composed of a resin reinforced with graphene, which is referred to as a “nanocomposite,” is used as an alternative to metal coating, since its low density makes it possible to obtain lighter materials than the original ones – limiting the aircraft’s mass, and therefore, its fuel consumption. But the electrically conductive materials required to dissipate the energy of the lightening strike have the drawback of reflecting electromagnetic waves, meaning that this kind of material cannot be used for stealth military applications.

To overcome this shortcoming, different forms of graphene have been developed to conserve its electrical conductivity while improving stealth. “Graphene foam” is one of these new structures. The wave penetrates the material, which creates a phenomenon in which the wave is reflected in all directions, trapping it and gradually suppressing its traces. It is not possible for the wave to return to the radar, so the aircraft becomes stealth. This is referred to as electromagnetic shielding.

Graphene for energy storage

Graphene has also become widely used in the field of electrical energy storage.

Graphene is an ideal candidate as an electrode for Li-ion batteries and supercapacitators. Its high electrical conductivity and high specific surface area (corresponding to the available surface on the graphene that can accommodate ions and facilitate the exchange of electrons between the graphene electrode and the lithium) makes it possible to obtain a large “storage capacity.” A large number of ions can easily insert themselves between the graphene sheets, which allows electrons to be exchanged with the current, increasing the battery’s electricity storage capacity, and therefore battery life. The ease with which ions can insert themselves into the graphene electrode and the high electrical conductivity of this material (for rapid electron transfer) result in a battery with a much shorter discharge/charge cycle. Graphene’s high conductivity makes it possible to deliver a great quantity of energy in a very short time, resulting in more powerful supercapacitators. Graphene is also a good thermal conductor, which limits temperature rise in batteries by dissipating the heat.

Electric batteries are increasingly pervasive in our lives. Graphene could help improve their performance. Markus Spiske/Unsplash, CC BY

At the industry level, Real Graphene has already developed an external battery that can completely recharge a mobile phone in 17 minutes. In an entirely different industry, Mercedes is working on a prototype for a car with a battery composed of graphene electrodes, proclaimed to have a range of 700 kilometers for a 15-minute recharge – at present, these values are quite surprising at first glance, especially for electric vehicles which require batteries with high storage capacity.

Making its way into the field of electronics

One area where graphene has struggled to set itself apart compared to semi-conductors is the field of electronics. Its electronic properties – due to its “band structure” – make it impossible to control electrons and graphene therefore behaves like a semi-metal. This means that the use of graphene for binary – digital – electronics remains challenging, especially for transistors, which are instead composed of semi-conductors.

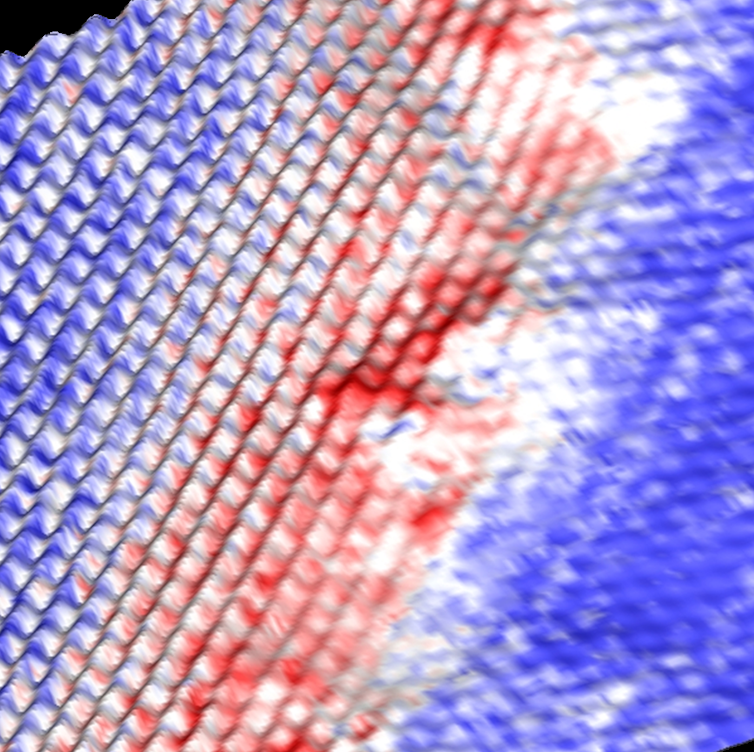

In order for graphene to be used in transistors, its band structure must be modified, which usually means degrading its honeycomb structure and other electrical properties. If we want to conserve this 2D structure, the chemical nature of the atoms that make up the material must be modified, for example by using boron nitride or transition metal dichalcogenides, which are also part of the family of 2D materials.

Microscopy of the interface between graphene and boron nitride(h-BN). Oak Ridge National Laboratory, Flickr, CC BY

If, however, we wish to use graphene, we must target applications in which mechanical properties (flexibility) are also sought, such as for sensors, electrodes and certain transistors reserved for analog electronics, like graphene field-effect transistors. The leading mobile phone companies are also working on developing flexible mobile phone screens for better ergonomics.

The manufacturing of the coming quantum computers may well rely on materials known as “topological insulators.” These are materials that are electrical conductors on their surface, but insulators at their core. Research is now focusing on the topological phase of graphene with electric conduction only at the edges.

The wide variety of applications for graphene demonstrates the material’s vast potential and makes it possible to explore new horizons in a wide range of fields such as optoelectronics and spintronics.

This material has already proved itself in industry, but has not revolutionized it so far. However, ongoing research allows new fields of application to be discovered every year. At the same time, synthesis methods are continually being developed to reduce the price of graphene per kilogram and obtain a higher-quality material.

Thibaut Lalire, PhD student in material science, IMT Mines Alès – Institut -Télécom

This article has been republished from The Conversation under a Creative Commons license. Read the original article (in French).